Hallman Foundry Capabilities

Hallman Foundry makes tough, high-quality iron castings for the rail and industrial industries. We’ve got the tools, the crew, and the know-how to handle every job that comes through our doors—and we take pride in doing it right every time.

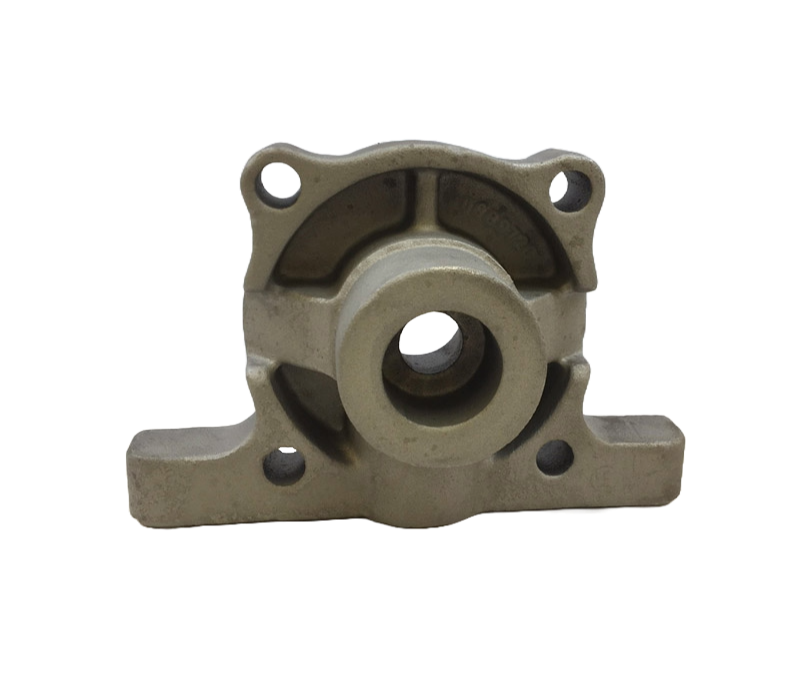

Casting Capabilities

Pour Gray and ductile Iron in a Green Sand Mold operation.

Castings range from a 1/2 lb. to 500 lbs.

Shell Cores, ISO Cure Cores and CO2 cores capable

2,000 square foot pattern shop. Includes metal, aluminum, wood, and epoxy capabilities and computerized solid model design

Equipped with the latest foundry technology including state-of-the-art spectrographic and metallographic lab

Molding Equipment

Hunter 20”x24”

2 units on-site

Offset to Cope Side

1 Molding line is equipped with Tru Flow System

Hunter 14” x 19”

Pin Lift Line

Manual Line

Up to 400 lb. Castings

Furnace 9 Ton IT6P

Machining Possibilities

We offer advanced CNC machining with a full suite of vertical milling and turning centers. Our milling capabilities include multiple machines.

CNC Milling Machines

Haas VF2SSCNC Mill

2 Units on-site

Full 4th Axis and Probing

30”x 20” x 20”

Haas VF2

Hardinge VMC

1000II 3 Axis CNC Mill

40” x 20” x 20” work envelope

CNC Turning Machines

SMEC SL2000Y W/LNS Bar Feeder

50” max bar length

Y & C Axis Live Tooling

Parts Catcher

Tall Stock

8” Chuck, Max Turn 14”, Max Length 21”, Max Swing 22”

Haas ST-20 CNC Lathe

8” Chuck, Max Turn 12”, Max Length 22.5”, Max Swing 21”

Mazak SQT15MS W/ATS ML-580 Bar Feeder

50” max bar length

C-Axis Live Tooling

Parts Catcher

8” Main Chuck and 6” Spindle

Max Turn 11”, Max Length 20”, Max Swing 20”

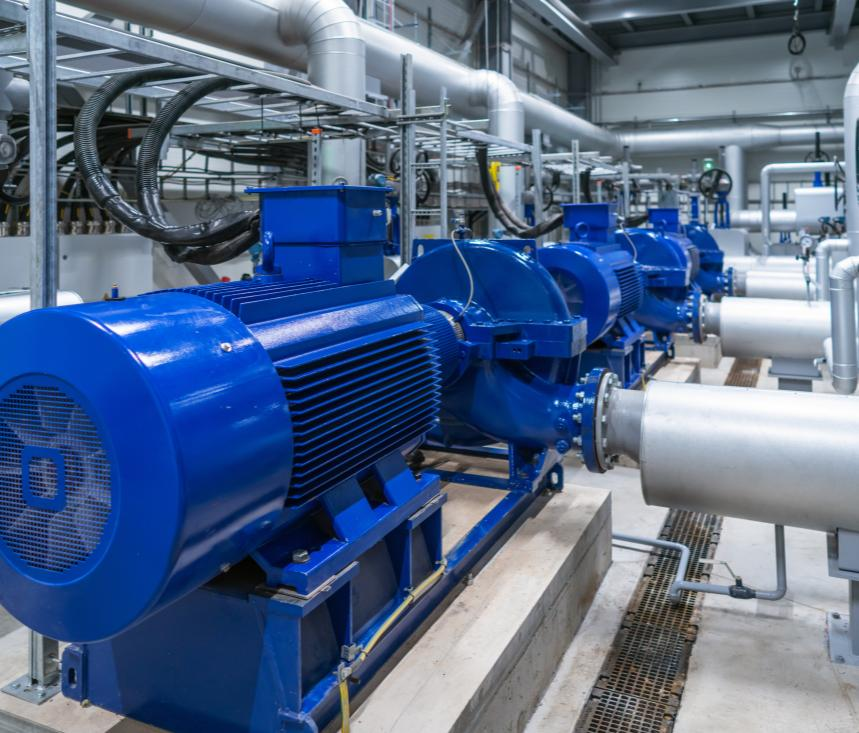

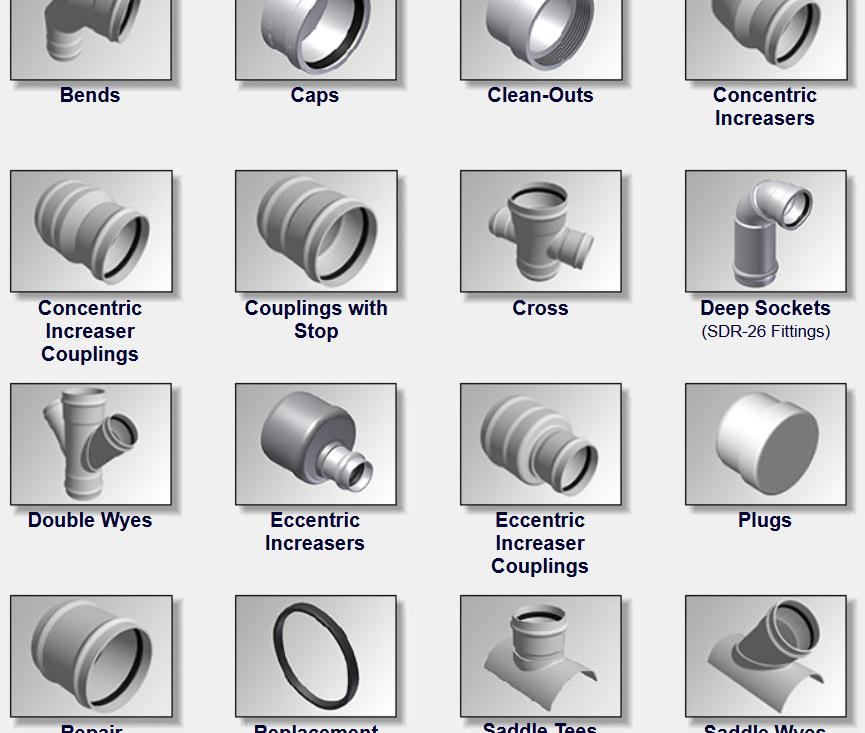

Serving These Key Industries

Our castings are designed for high-performance applications where strength, precision, and reliability Matter Most.

Transportation

Railroad

Heavy Truck

Pumps/Valves

Water Systems